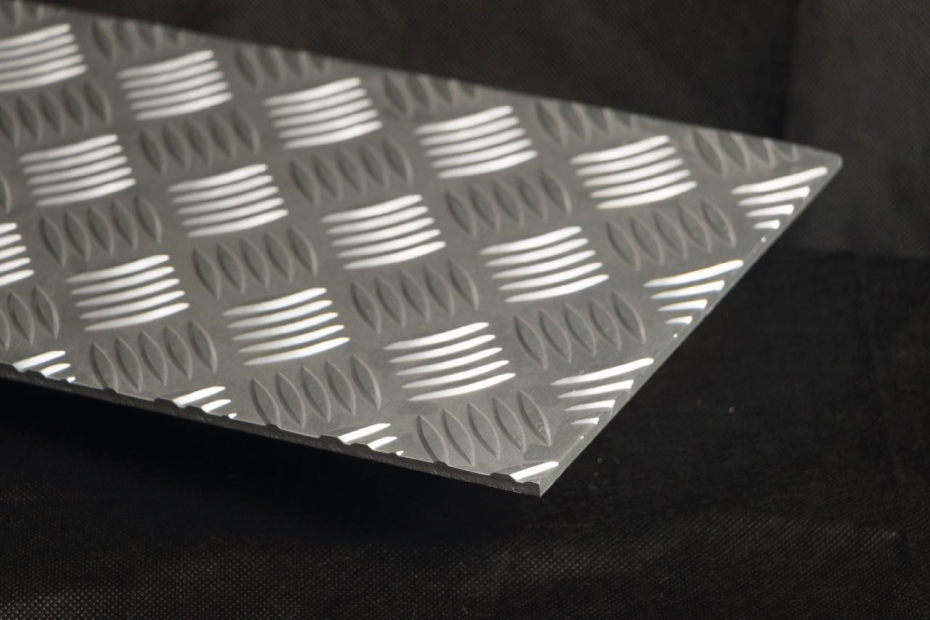

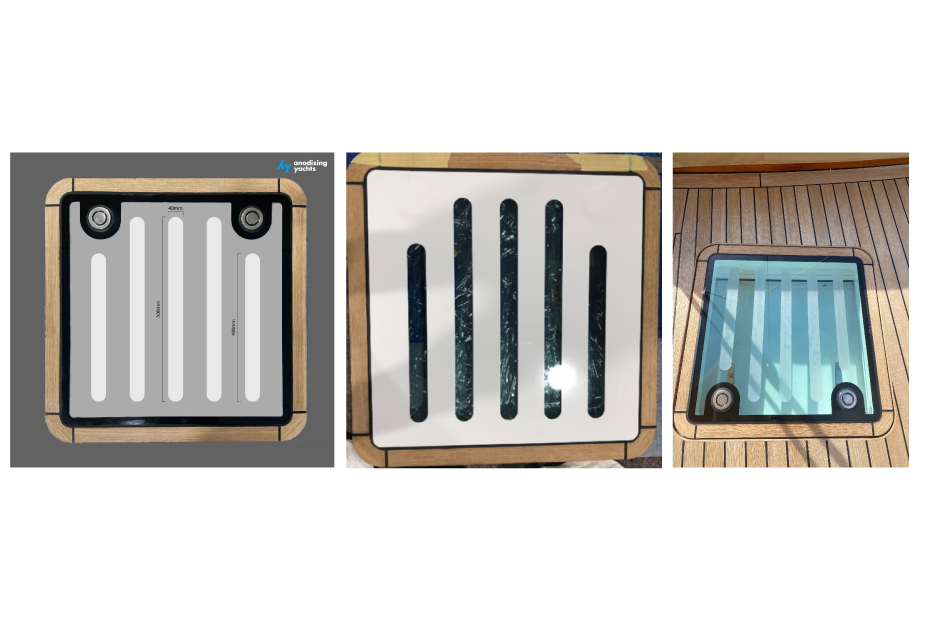

ANODIZING AND HARD ANODIZING

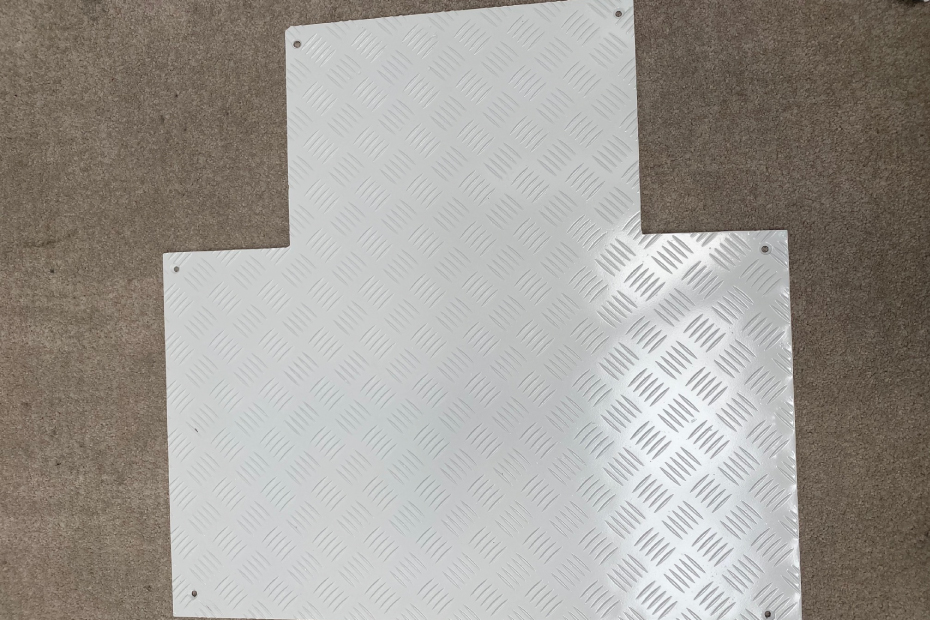

- Anodizing: this electrochemical process passes a direct current of about 2000A with a voltage of 10V or 15V through the material to be anodized, depositing a thin layer of oxide that will gradually become part of the material, giving it multiple properties. All colors except white.

- Natural: Application standard S/N MIL-A-8625F TIPO II CL 1

- With coloring: Application standard S/N MIL-A-8625F TIPO II CL 2

- Hard anodizing: it is achieved at low temperatures (0ºC) in a strong current density and with a voltage that can rise to 80ºC or 100ºC depending on the material to be treated. A vigorous stirring with effective cooling is necessary. As thicknesses achieved are higher than those of conventional anodizing, the hardness is also higher. It is applied to parts subject to friction.

- Natural: Application standard S/N MIL-A-8625F TIPO III CL 1

- With coloring: Application standard S/N MIL-A-8625F TIPO III CL 2

Advantage:

- Higher abrasion resistance.

- Protection against corrosion.

- Surface uniformity.

- Extension of the useful life.

- Better cleaning.

- Greater hardness on the Surface.

- It is not affected by sunlight.

- Good thermal insulator.

- Aesthetic improvement.

- Lightness.

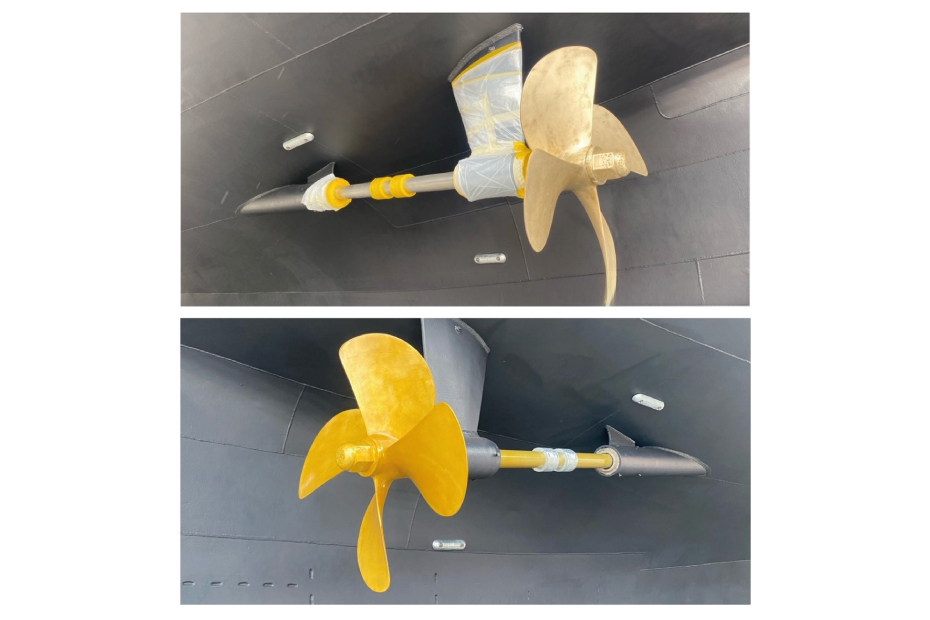

GOLD, SILVER AND COPPER COATING

- Gold plating: Method used to deposit a layer of gold on the metal surface, through chemical or electrochemical processes, in order to protect other metals from corrosion and give it a better visual and decorative appearance, in addition to its great electrical conductivity. It is carried out by means of an exchange reaction with the help of some catalyst.

It can be applied on iron, steel, brass, copper, aluminum, silver, Zamack, pewter, etc.

It is especially used for the electronic and nautical industry, normally for integrated circuit boards as they offer great resistance to corrosion and a high conductive capacity to copper layers.

It ends with an oven lacquer at 120ºC to guarantee greater hardness, resistance and durability of the pieces.

- Silver plating: It offers the highest electrical conductivity of all metals however it has the drawback that it rusts quickly. For engineering reasons, silver is recommended for pieces that have to be welded, where high electrical and thermal conductivity, wear resistance and good corrosion resistance are required.

It ends with an oven lacquer at 120ºC to guarantee greater hardness, resistance and durability of the pieces. - Copper plating: Mainly used as a base coat before another coating, usually nickel, but it is also used as a single coating, both to transform non-conductive materials into conductors, and to improve the electrical conductivity of components on integrated circuit boards.

Advantage:

- Corrosion resistance.

- High conductive capacity.

- Greater hardness.

- Greater resistance.

- Greater durability.

- Aesthetic improvement.

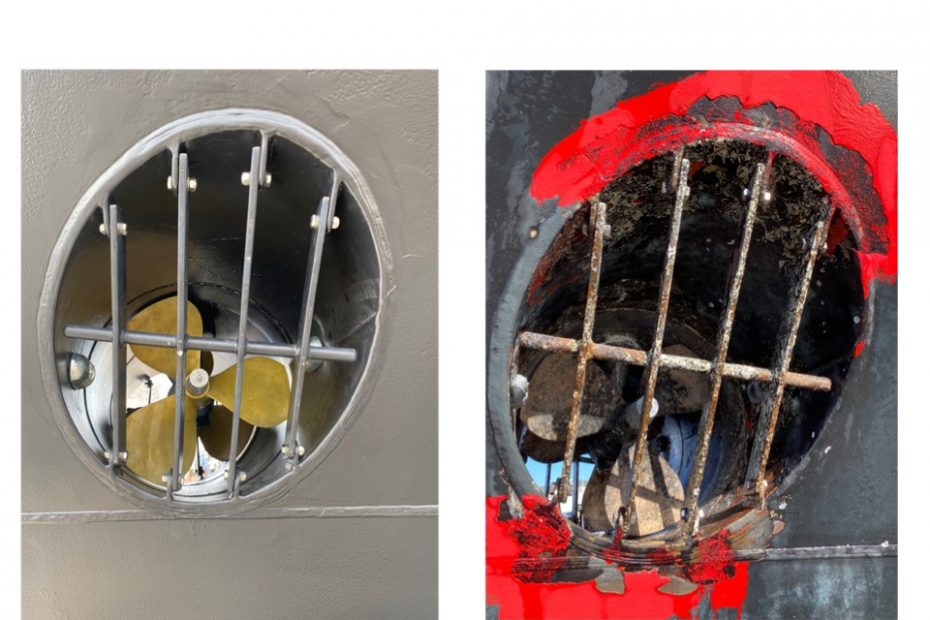

SAND BLASTING

Projection of abrasive materials (previously selected according to the surface to be cleaned as well as the roughness to be achieved) at high speed on the surface of a substrate. The impact of these abrasives cleans the surface of impurities (such as surface oxides, lamination scale, incrustations of foreign materials …) generating a certain roughness favorable for adhesion and anchoring of future paint layers. This gain in roughness can also be used in more decorative finishing work to achieve a certain grip, for example on glass floors.

As the impact of the abrasives produces excellent roughness to anchor the next layers of paint Sand Blastingt is an efficient and effective mechanical procedure for cleaning and preparing metal surfaces prior to the painting process. The level of roughness is mainly determined by the size and shape of the abrasive material. This process is also used for other more decorative purposes where there is no paint application afterwards, taking advantage of its roughness generation function in the piece to be treated.

The abrasive material could reach high temperatures during the impact process and due to factors such as working pressure, nozzle diameter, distance, angle … melting and becoming part of the blasted surface ( this effect is known as triboplasm ). That is why the blasting abrasive material must be carefully selected according to the material to be treated in order to avoid galvanic torques and contaminate the new surface.

Main applications:

- Cleaning and removal.

- Decorative finishes.

- Engravings.

- Shot peening.

Advantage:

- Maintenance of the strictest dimensional tolerances of the treated parts.

- Total homogeneity in the surface finishes obtained.

- Really unique look and feel with a different finish than untreated matte.

- Minimum operating costs.

- Uniform and repeatable results.

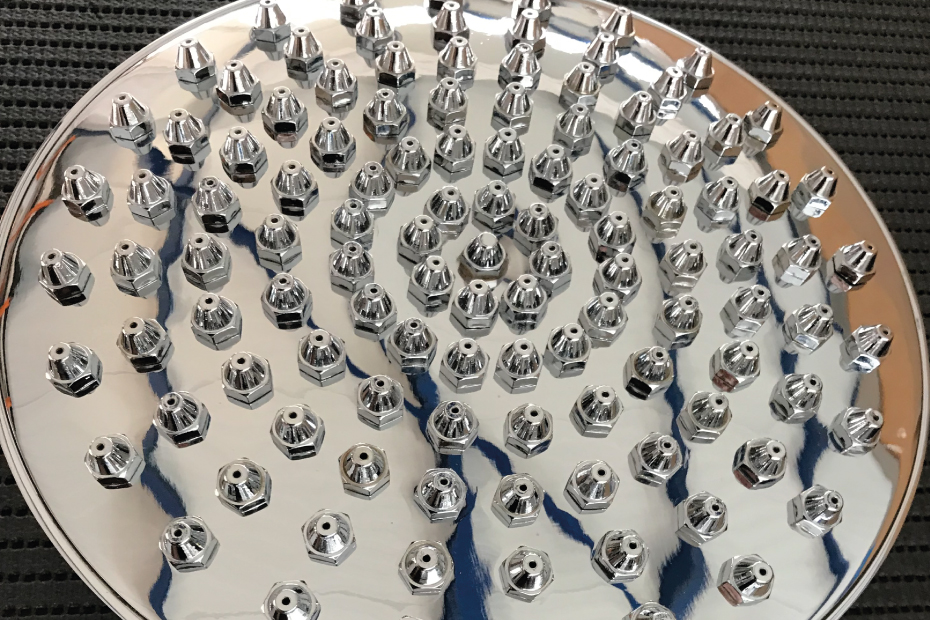

CHROME-HARD CHROME COATING

Electrolytic coating process consisting of immersing the surface to be treated (cathode) in an electrolyte in which pieces (anode) of high purity of the metal that is deposited (Chromium) are submerged, keeping the concentration of the metal ions in the electrolyte constant, in order to protect it against chemical attack, give it a high surface hardness and change its visual appearance.

The metals to be treated can be iron, brass, aluminum, stainless etc.

Phases:

- Pickling: it is done with a solution of sulfuric, hydrochloric acid and water.

- Polished: in charge of eliminating residues, damages, and leaving a uniform surface so that the nickel and chrome plating process does not copy it and defects aren’t seen in the material once the processes are finished.

- Degrease the parts: using a solvent (sodium hydroxide) so that the nickel process has a good adhesion.

- Nickel plating: application of a nickel layer that gives it thickness, greater coating, protection against corrosion and generates mordant to the chrome layer.

- Chroming: application of chrome layer to give greater thickness and coating, protection against corrosion and a decorative finish.

1. Decorative chrome: Thin layers of chrome are deposited on the surface to improve the appearance of the pieces (tools, knobs, handles, bathroom accessories and automotive parts). The final finish is bluish white and reduces oxidation.

2. Hard chrome plating: A thick chrome layer is deposited providing the material with resistance to corrosion and wear. It is used for industrial components that must withstand high friction, impact or high temperatures (valve seats, bearings, crankshafts, piston shafts, …) or for a worn element to recover its dimensions.

Advantage:

- Maintenance of the strictest dimensional tolerances of the treated parts.

- Total homogeneity in the surface finishes obtained.

- Really unique appearance.

- Aesthetic improvement.

- Minimum operating costs.

- Uniform and repeatable results.

- Corrosion resistance.

- Great resistance to wear.

- Good coefficient of friction.

- High hardness.

- High temperature resistance.

- Recovery of worn surfaces.

- Hardness 70 RC = 1100 Vickers.

- Melting temperature 1800 Cº.

- Excellent for application when friction and slip are important

- Thickness from 5 to 500 microns

- Machinable, by means of grinding, allowing pieces to be adjusted to the desired tolerance.

Application standard ASTM B 456-95.

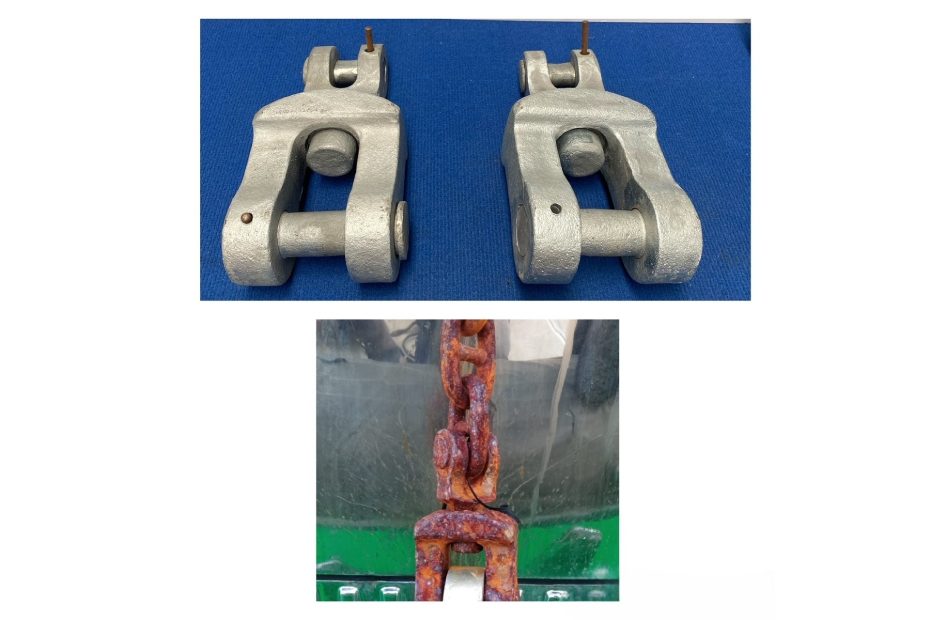

GALVANIZING AND HOT GALVANIZING

Process carried out to obtain a Zinc coating.

- Hot dip galvanized: The Zinc coating is chemically bonded to the steel base because there is a diffusion metallurgical chemical reaction between Zinc melted at 450 ° C and Iron or steel by immersion. Several surface layers of zinc-iron alloy have been formed ( with solidified Zinc ) by removing the steel from the bath. These different alloy layers are harder than the steel base and have an increasing Zinc content as they get closer to the surface of the coating.

- Galvanized projected: On metal surfaces previously prepared by sandblasting or shot blasting, by means of Zinc semi-cast spray with a Zinc powder-fed spray gun.

Advantage:

- Prevents the oxidation and corrosion that humidity and environmental contamination can cause to iron.

- Huge durability (20-40 years in an industrial environment, 10-20 years in a marine environment).

- Zero maintenance cost.

- Great versatility.

- Great resistance to shocks and abrasion.

- A galvanized metal can be over painted and stainless steel and aluminum can be combined, both to modify its aesthetics and to further increase its durability.

Application standard S /N ASTM A 123

(Application standard ASTM A 510-Grado 1008: material de fabricación)

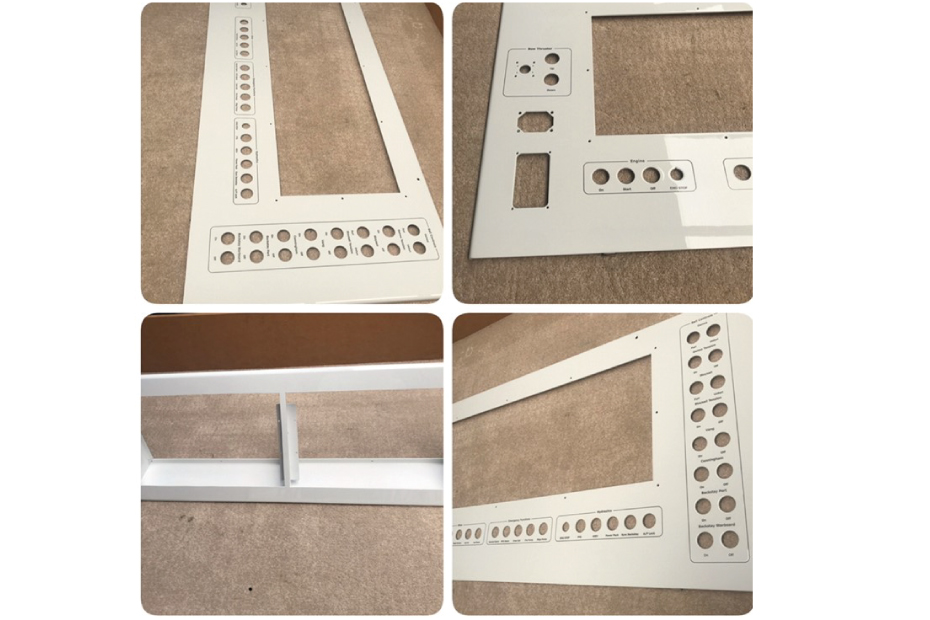

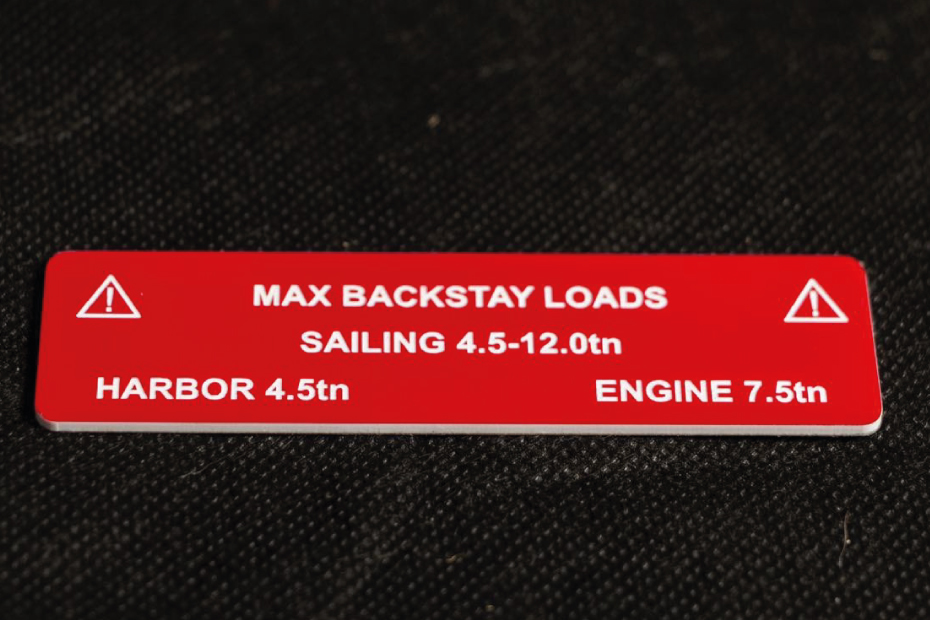

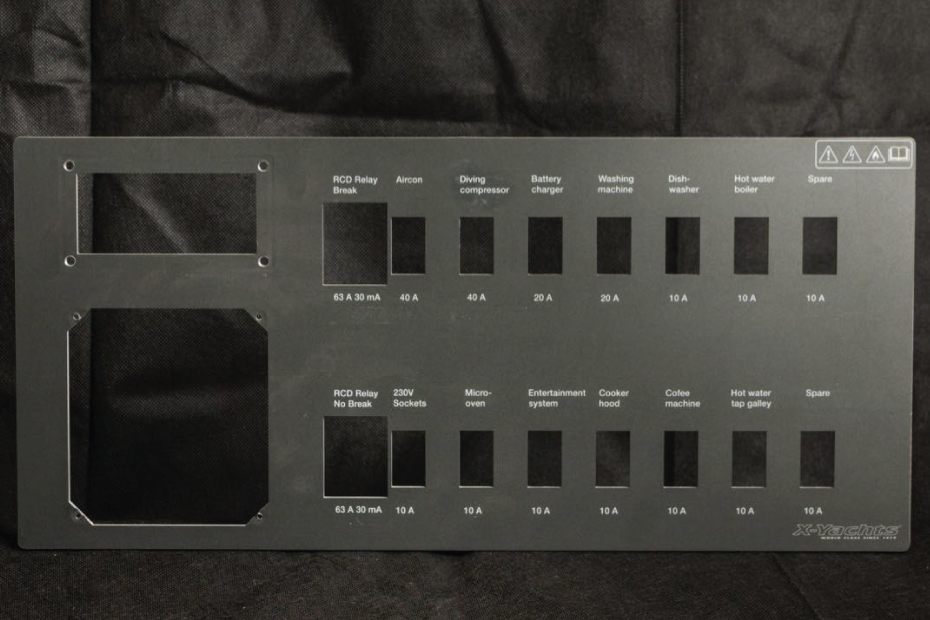

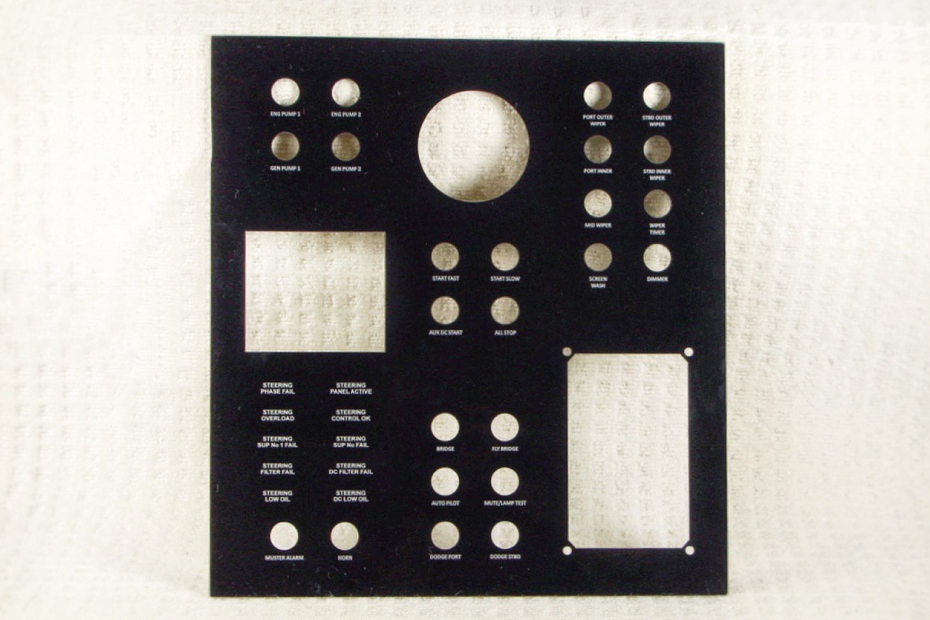

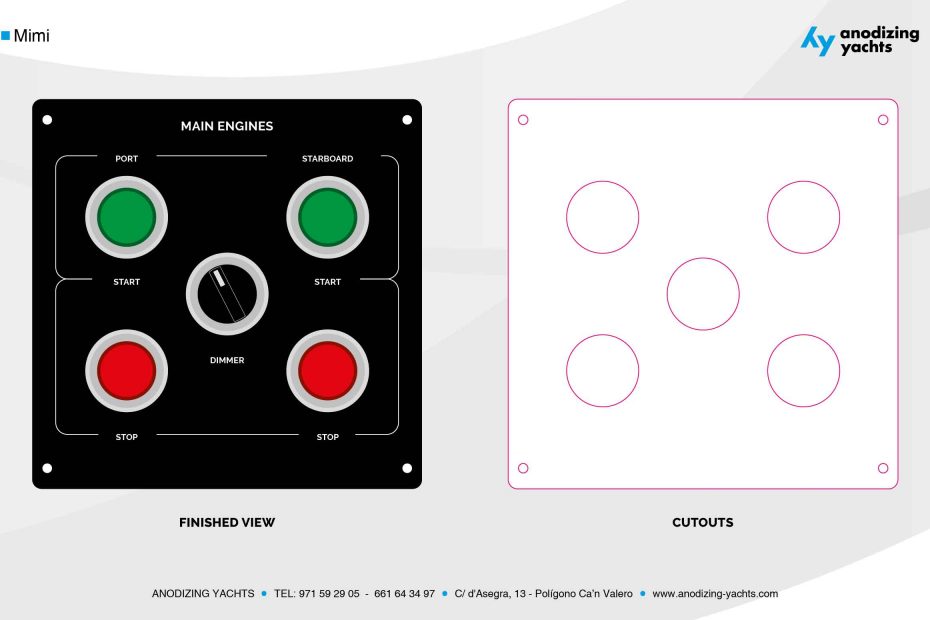

LASER ENGRAVING AND CUTTING

- Laser engraving:

- Laser: it is a superficial marking on metals and in depth on acrylic or wood materials. This option is only indicated for interior if marked on metals.

- CNC: the reduction of the material is carried out by means of a milling cutter or burin that strips the material.

- Chemical: reduction of the metals by means of an acid, this option allows to leave the engraving unpainted, especially in stainless steel, since the recessed surface is matt and offers a nice finish.

Multitude of materials such as stainless steel, brass, copper, corten steel, methacrylate, aluminum, wood,… can be engraved.

- Cutting of materials:

- Laser: for cutting only metals up to 5 mm. Fine cut and well defined, does not require repulse the piece.

- By water: cut any material, up to 20 mm in most metals and up to 150 mm in other types of non-metallic materials. The finish requires the polishing of the piece.

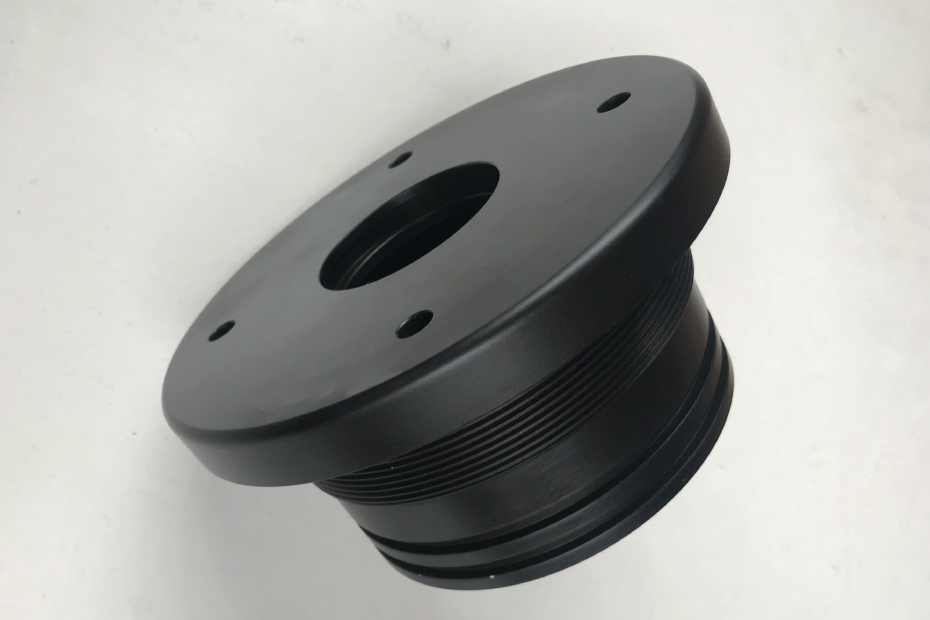

NICKEL AND CHEMICAL NICKEL COATING

1. Chemical Nickel Plating: this procedure deposits a Nickel-Phosphor alloy without any external current source.

It offers exceptional technical solutions for its unbeatable qualities of hardness, resistance to wear, friction, abrasion, corrosion …Most remarkable features:

Uniform thickness: provides exactly the same protection against corrosion in all areas of the part. It differs from the electrolytic coating in that it deposits very different thicknesses from one point to another of the piece, beginning the corrosion in these areas where the deposits are weaker.

Variable properties according to the heat treatments carried out: the influence of the heat treatments is due to the fact that the deposition of Chemical Nickel is an alloy, so that its molecular structure changes in the presence of temperature. One of the most common heat treatments is the one we apply to increase the hardness of the coating that can reach 1,100 Vickers.

It can be applied on most metals: such as cast iron, carbon and alloy steels, stainless steels, aluminum, copper, cobalt, monel, nickel and alloys, gold, silver, uranium … even certain thermoset plastic materials such as bakelite, melamine , ceramic, glass, as long as we apply a powerful catalyst to its surface.

Application standard S/N AMS C 26074 Y ASTM-733B.

2. Nickel plating: it consists of the application of a Nickel layer on the surface of an object. The purpose, generally, is to improve resistance to corrosion, either for decorative reasons or as a base for other electroplating coatings.

Application standard S/N MIL-P-27418.

Advantages:

- Increases resistance to corrosion.

- Provides hardness.

- Wear resistance.

- Friction resistance.

- Abrasion resistance.

- Low vibration resistance.

- Uniformity.

- Guarantee to thicken.

- Semi-gloss result.

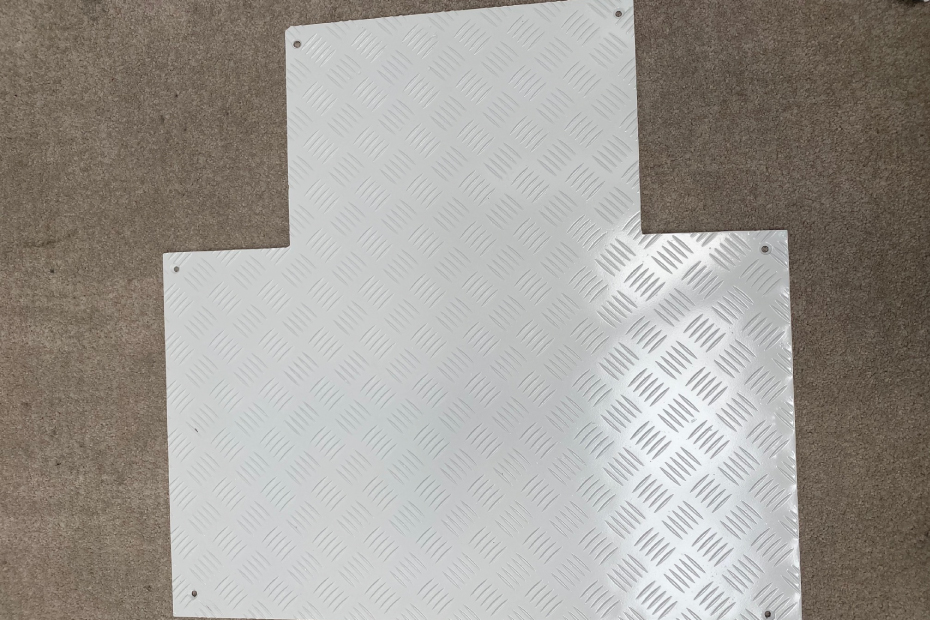

SELF-LEVELING LOTUM FLOORING

The SELF-LEVELING LOTUM system is a continuous coating consisting of a combination of resins and aggregates, with high mechanical resistance. It is an ideal flooring for both industrial and decorative environments, thanks to its excellent properties and the wide variety of finishes available.

It has a series of characteristics, such as being continuous and easy to clean, as well as being flexible to absorb possible movements of the metal substrate in an area where vibrations can occur and to be applied to create a smooth surface on a substrate with different height levels. These materials do not generate odors as they are solvent-free.

Its main properties and characteristics are:

- Aesthetic finish.

- Approved according to the requirements of the Technical Building Code.

- Bfl-s1 fire behavior according to UNE EN 13501 standard.

- Suitable for the Agri-Food Industry according to European Regulation 852/2004.

- Easy cleaning and maintenance.

- Continuous, without joints.

- Excellent resistance to abrasion.

- Possibility of non-slip finish.

- Available in RAL chart colors.

- Possibility of finishing with decorative chips.

- Excellent chemical resistance.

- Applicable on a wide variety of substrates: Concrete, ceramic, asphalt, metal, old resins, …

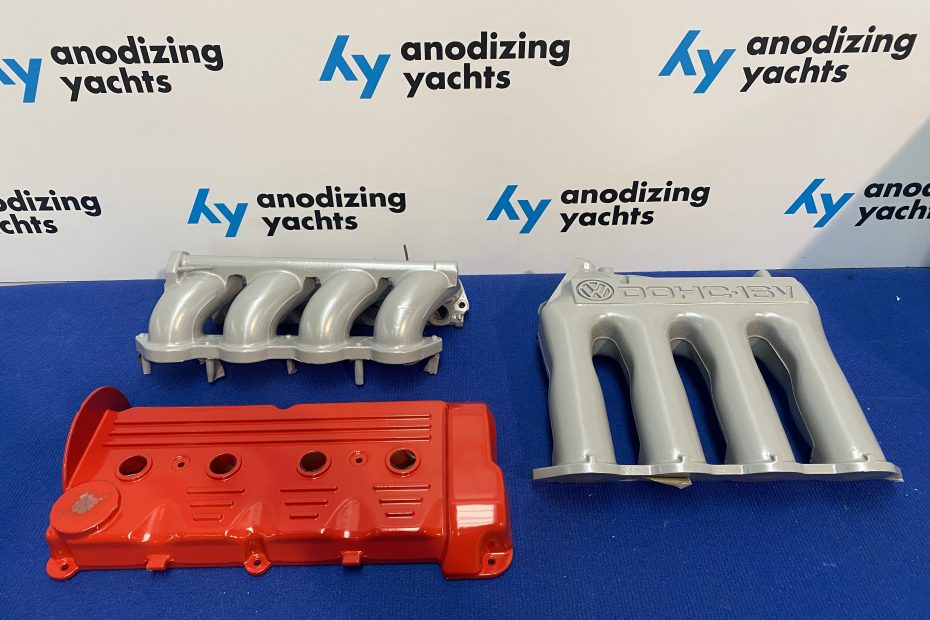

PAINTING

Painting process is the set of operations necessary for the application of a paint in order to satisfy and comply with the previously established quality, cost, colour, deadline and safety requirements.

Paint is defined as a coating material in a liquid or solid state which adheres and hardens to form a film that protects, decorates or adds some specific function to the surface on which it has been deposited after being spread on a Surface.

Phases of the painting process:

- Surface preparation: Elimination of any contaminant that could be found on the surface to be painted and creation of mechanical and / or chemical anchors (roughness, increase in surface energy, etc.) to favor the adhesion of future paint layers. It will depend on the contaminants that you want to remove, the degree of anchorage / adhesion that we want to obtain and especiallly on the composition, geometry and thickness of the material we want to prepare.

- Cleaning and degreasing of surfaces: Its purpose is the elimination of different contaminants that may exist on the surface of a material, such as fats, oils, dust or others, due to the transport, handling or storage of materials.

- Masked: Its main objective is to protect certain areas or areas of the structure or part that we do not want to paint.

- Primer application: Set of coatings applied as the first layer of the paint system to protect the surface from corrosion and facilitate adhesion to the following layers of Paint.

- Application of the paint: It begins with the operation of mixing the components that make up the paint, generally most of the current paints are 2-component (resin and hardener) that have to be mixed homogeneously under the parameters indicated by the manufacturer of paint to obtain the desired viscosity. The selected technique for applying the paint (brushes, rollers or gloves, spray guns, electrostatic guns, immersion, electrophoresis, etc.) will depend on parameters such as the number of pieces to be painted, the geometry and size of this pieces, part material, aesthetic requirements, environmental regulations, cost, selected paint products, etc..

- Curing of the paint: Waiting time in which the paint goes from a liquid state to a solid state (drying time). It can be decreased by using the right tools and materials.

Curing = Drying (process of evaporation of all solvents and diluents added to the paint in order to make it liquid or to reduce its viscosity) + Hardening (the main resin of the paint is created and then hardens with all the other pigments and additives that compose it, creating a solid and adherent coating).

7. Final inspection

Advantage:

- Protection against oxidation, corrosion and material degradation.

The insulating layer between the material and the exterior prevents the action of external agents such as humidity, saline environments, ultraviolet radiation, chemical products, etc. which can induce and cause phenomena such as oxidation, corrosion or degradation to the material.

- Decoration and beautification of materials and surfaces.

It is possible to achieve a wide range of colors as well as decorative effects (chameleon effect, mercury effect, etc.) which enhance and make surfaces more attractive due to the pigments and additives incorporated in the paints.

One of the advantages of Anodizing Yachts is that we have a spectrophotometre to read the color that is applied to the part, formulate it and make a paint repair without changing the color of it.

Application standard ASTM D3276 – 15.

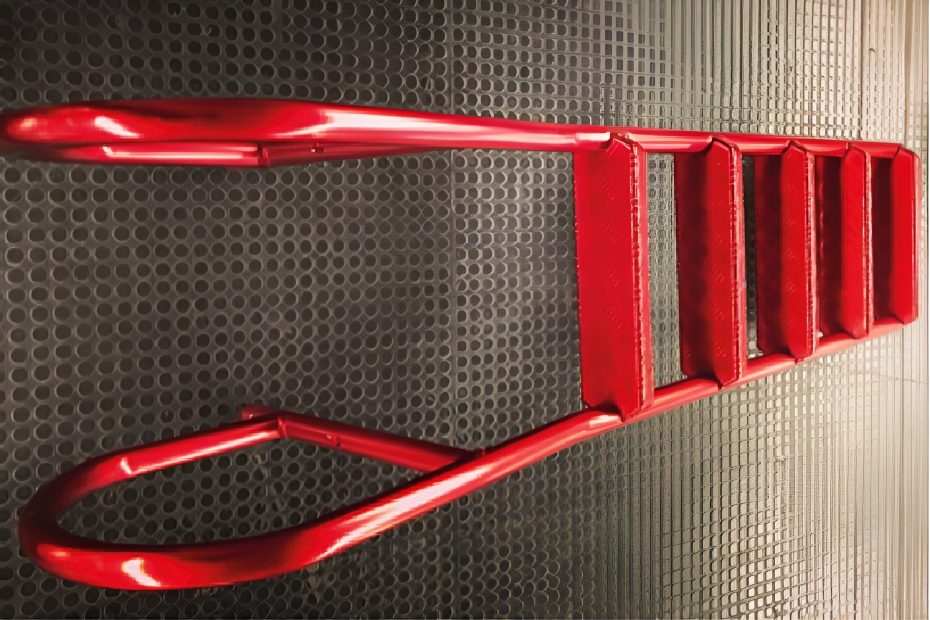

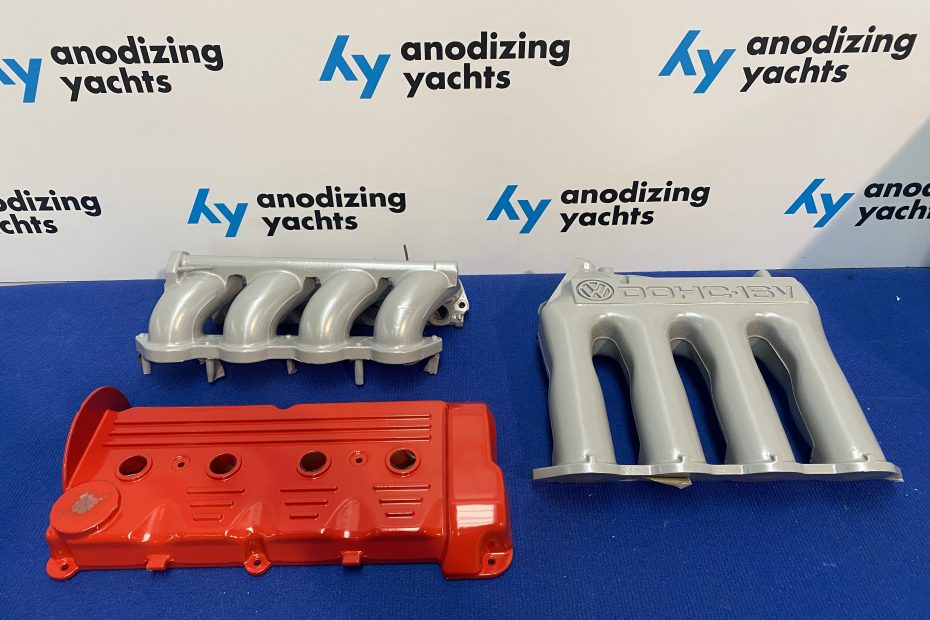

POWDER COATING

Electrostatic application of organic powder to metal parts that require coating for protection or decoration. The most widely used method is the application by means of electrostatic guns that transfer an electrical charge to the particles that make up the powder paint at the gun outlet. Once charged, the paint is attracted and covers the entire surface of the piece, which is electrically charged with an opposite sign, resulting in attractive forces between the paint and the piece to be painted responsible of covering the entire of the part surface. Once the piece is covered with powder, it melts on the surface by exposing it to high temperatures (over 200ºC). Then it cools, resulting in a coating perfectly adhered to the surface of the piece.

This type of coating the material is 100% solid and is in a dry state in the form of a fine powder. Once the powder is applied, it covers the surface of the piece and melts into it through the application of heat, generating a highly adhered layer to the surface and providing it with properties of resistance both chemical (corrosion, aggressive chemical agents …) and physical (light, hardness …), as well as aesthetic properties (color, shine, desired texture …). They are also called thermosetting paints or electrostatic paints.

They consist of resins (epoxy, polyester, epoxy-polyester, polyurethane, acrylic), hardeners, pigments, fillers and additives (anti-graffiti, antimicrobial, antistatic …). It is a 100% solvent-free paint system.

Phases of the process:

- Pre-treatment:

- Abrasive, mechanical or chemical cleaning.

- Drying.

- Cooling.

- Application of the powder: the powder is electrically charged as it is applied to the piece, giving each particle a negative charge. The part to be coated is electrically grounded as a means of attracting and bonding the charged powder to the surface of the part in a uniform layer of dry powder.

- Curing: the piece is introduced into the curing oven in which the powdered gels flow and cure, generating a smooth product with a long-lasting finish, through a chemical crosslinking reaction between the powder particles.

Advantage:

- Greater durability and resistance to corrosion.

- More uniform coating and brighter and fresher color.

- Aesthetic defects such as sagging do not occur as powder paint is not in a liquid state when applied.

- Waste reduction.

- Greater application layer.

- Greater hardness and resistance to friction.

- Lower operating costs with the possibility of automation, less waste produced and less disposal costs (very low overspray, providing high application rates as well as recovery of the paint not transferred to the part, reaching values of around 98% of use of the material).

- They are more ecological as they do not contain solvents, in addition to being able to recover the leftovers in a hopper and reuse them, with negligible waste.

Safety and hygiene:

- 100% ecological paint system with the use of materials free of VOC (volatile organic compounds) and do not contain solvents. Less risk to health, less risk of fire, …

Application standard ASMT D3451 – 06 (2017).

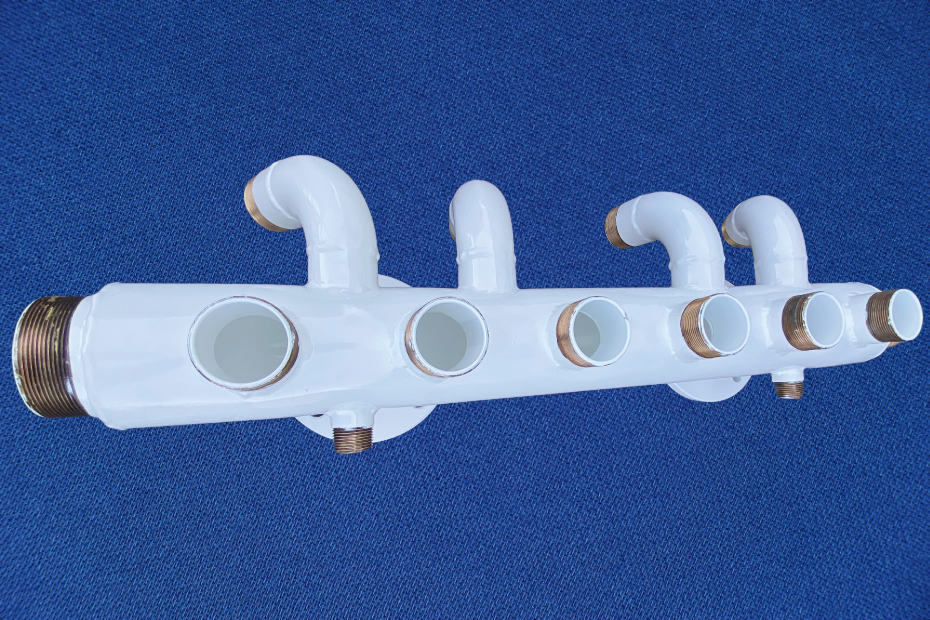

PLASTIC COATING

Innovative alternative to other conventional finishes. It can be applied in pieces from a few centimeters to meters, in a wide range of colors and on a variety of materials such as steel, stainless steel, aluminum, copper, galvanized metals, galvanized, glass, etc..

- Thermoplastics:

- Electrical isolation.

- Acoustic isolation.

- Chemical stability.

- Suitable for food and drinking water.

- Thermides: Traditional materials suitable for all types of parts and that are generally applied by electrostatic projection. High surface hardness.

- Polyureas: Materials of extraordinary resistance to wear and abrasion applicable on any surface (wood, concrete, metal, …) achieving a continuous membrane several mm thick. Products suitable for contact with food and drinking water.

- Liquids: Finishes of delicate pieces with resins and varnishes of great resistance that contribute to the finished pieces, aesthetic finishes of the first order. Special textures, high scratch resistance and a great aesthetic finish are achieved.

Advantage:

- Excellent corrosion resistance (Application standard ASTM B117).

- Zero loss of adhesion (Application standard ASTM D3359-A).

- Good weathering behavior and UV rays (Application standard ASTM G154-06).

- High resistance to impact and abrasion (Application standard ASTM 926-94).

- Chemical stability in aggressive environments (Application standard ASTM A956-94).

- Flexible coatings.

- Electrical and food insulation.

- Smooth, shiny and pleasant touch finish.

Application standard ASTM F1043-08 and F668-07.

ZINC COATING

Cold electrolytic process in which a zinc layer is adhered to the steel to protect it against corrosion subsequently stripping it by electrodeposition.

It is used instead of galvanizing when lower corrosion resistance and lower mechanical strength but higher aesthetic qualities are required. Less thickness than galvanized.

Advantage:

- Improvement in the persistence of the paint.

- Nice appearance.

- Low cost.

- Improvement against corrosion.

- It can be colored by passivating it.

Application standard S/N ASTM 633-07 Y UNE-EN-12329.

(Application standard ASTM A 510-Grado 1020: material de fabricación).

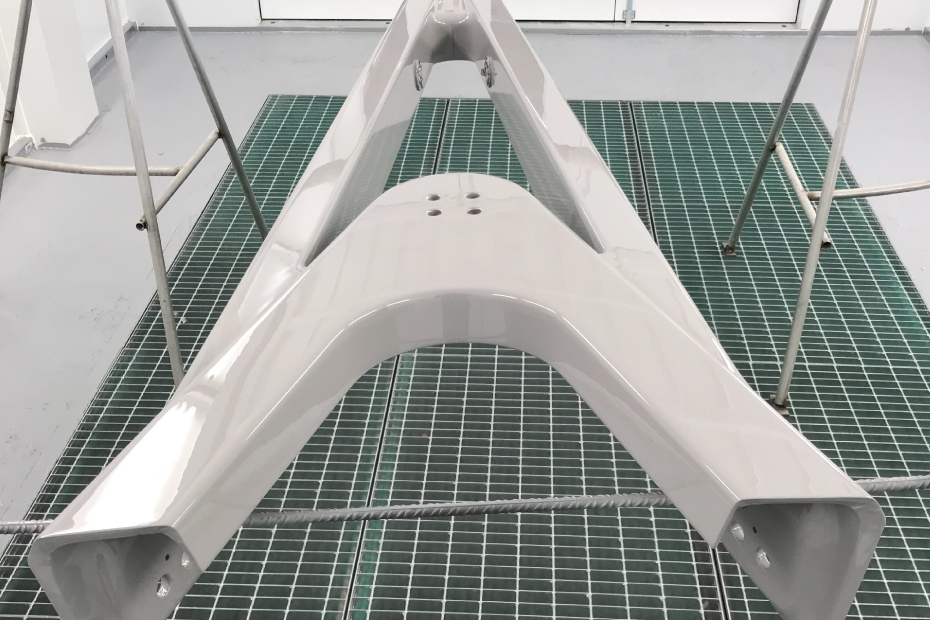

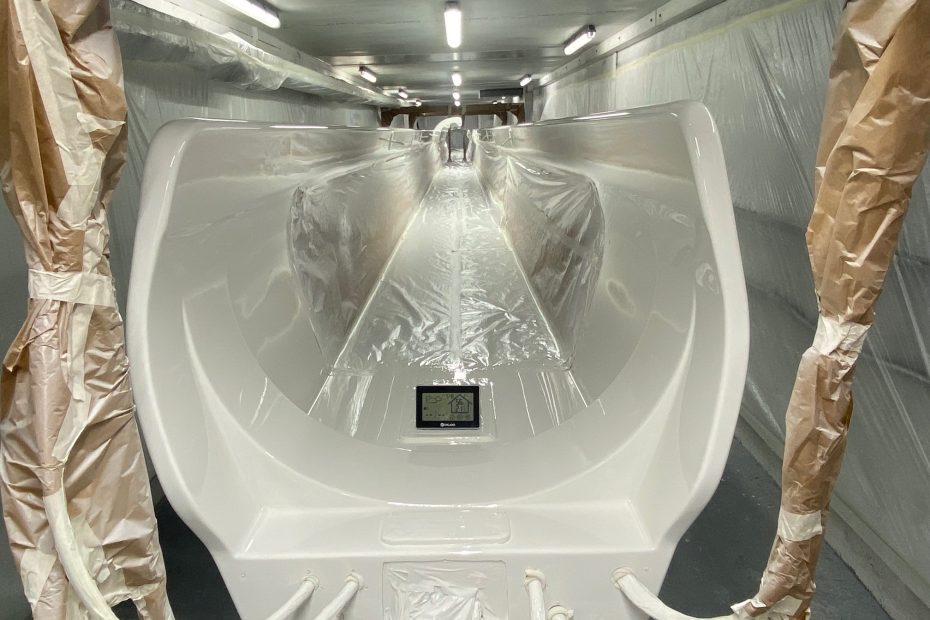

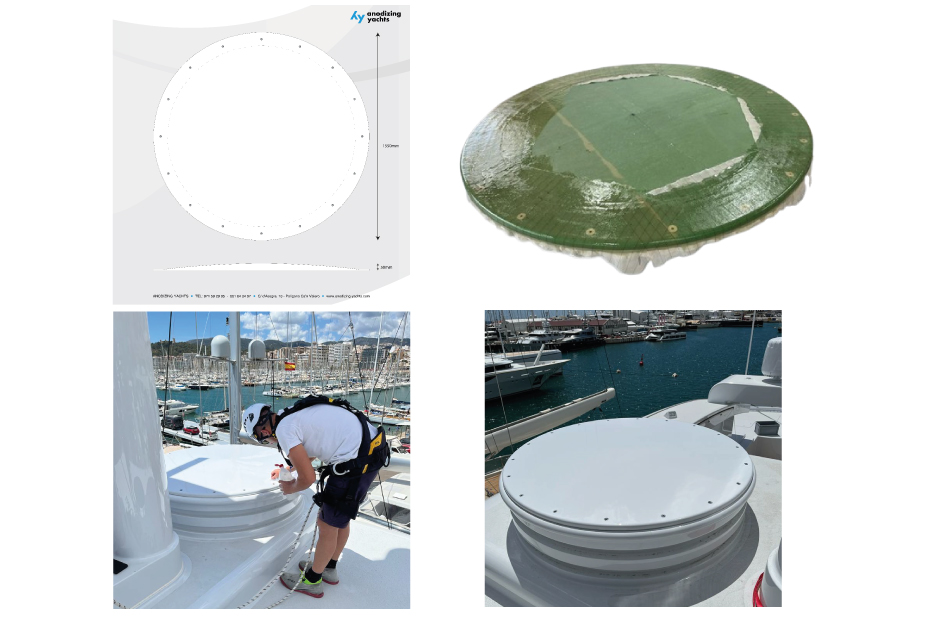

FIBRE

Anodizing Yachts repairs cracks, delaminations, dents and other damage on surfaces and structures made of fiberglass or carbon fibre. It also offers solutions in fibre manufacturing, in the hull or on the deck, both carbon and glass. Since Anodizing Yachts also specializes in gel coat repairs and finishes, as well as painting, it can handle any type of job/project, from beginning to end, starting with repair or fabrication through to completion in the desired finish.

Fibre repairs return the required resistance in the areas to be treated, integrating them with the surrounding areas. The fabrications that we develop are adapted to the needs of clients, collaborating with our experience to achieve the objective desired by the client, both in the functional and aesthetic aspects.

Advantage:

- Adaptation to customer needs.

- Recovery of resistance in the repaired areas.

- Excellent finishes.

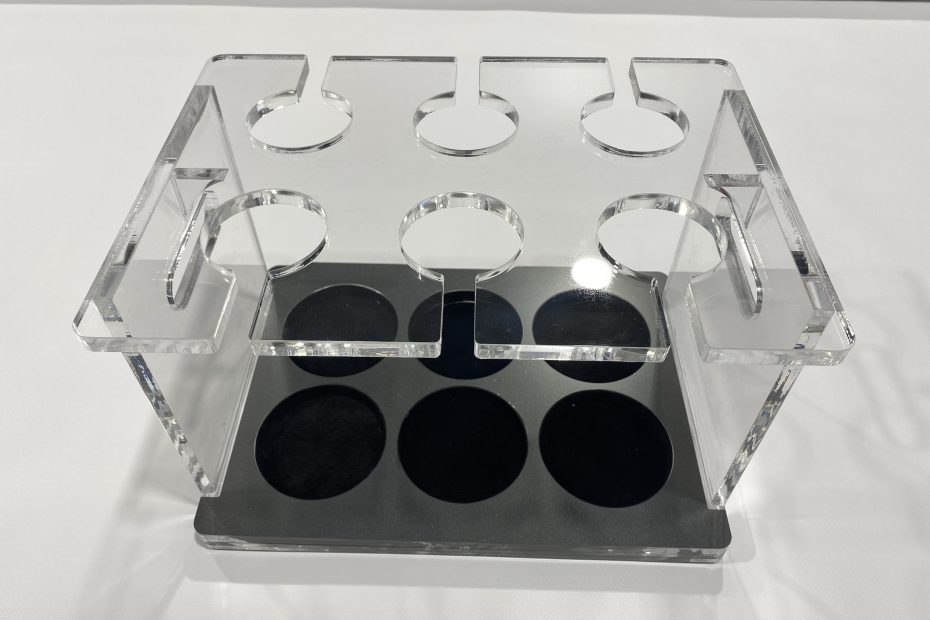

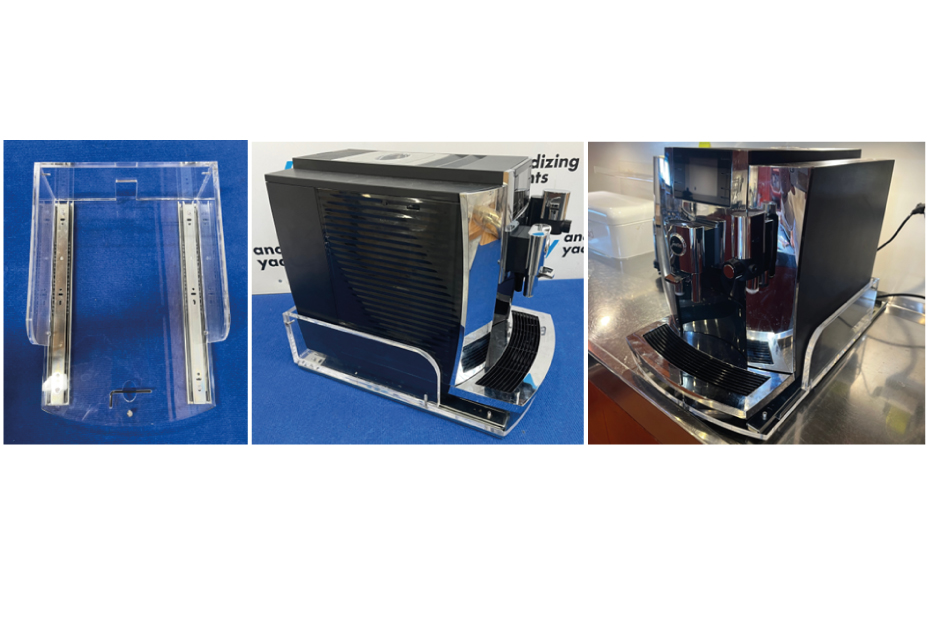

METHACRYLATE / “PERSPEX”

Anodizing Yachts carries out works in methacrylate in all its applications, adapting to the needs of the client, and contributing with our experience both in design and in its functionality.

The necessary cuts are made with state-of-the-art machinery, giving the best finishes and precision in measurements.

The works in methacrylate can be combined with the capacity and experience that the company has in text engravings, figure designs and vinyl finishes, when necessary.

Among the works carried out are doors, protective control panels, control panels, shelves for all types of containers, glasses, cups and sizes, separators in different shapes and volumes, etc.

Advantage:

- Creation of any type of design.

- Excellent finishes.

- Process optimization including other capabilities of Anodizing Yachts.

- Durability

EPOXY RECONSTRUCTION

By using epoxy adhesive paste you can achieve filling surfaces and repairing areas in a very quick time. It can be applied locally and offers excellent adhesion to porous or non-porous surfaces. It can be applied to vertical surfaces without sagging and cures overnight with negligible shrinking.

Advantage:

- Cures at room temperature.

- Offers excellent adhesion to porous or non-porous surfaces.

- Offers good machining qualities (sanding, drilling, tapping).

- Offers excellent compressive and tensile strength, Developing Strength Rapidly.

- Resists alkalies, dilute acids and solvents.

- Stopping leaks in pipes, valves and tanks.

- Bonding like and unlike surfaces.

- Filling metal joints, dents, etc.

- Anchoring bolts in wood, concrete, etc.

- Repairing metal surfaces.

- It can be used in composites, metal, wood, etc.

- It can be used as a barrier to protect against galvanic corrosion occurring with dissimilar material surfaces in contact.

- Cost reduction: no need of special equipment, application time and easy access.

ELECTROPOLISHING

Electropolishing is an electromechanical process where the surface of stainless steel is passivated.

Electropolishing is done in accordance with standard ASTM B912-02, “Passivation of Stainless Steels Using Electropolishing”. Prior the electromechanical process starts, the article is cleaned and acid pickled following standard ASTM A380. Then the article is introduced in an electropolishing solution for a period of time at the current density and temperature required to produce the passive surface and required surface finish, if any. Proprietary electropolishing solutions are available offering special features such longer life, better bright throwing power, etc.

Advantage:

- Improved corrosion resistance and better bright throwing power.

- Smoother surfaces by decreasing rugosity, some metal is removed from the surface of the article, from 3 to 15 µm.

- Extreme cleanliness and decontamination.

- Removal of heat tint and oxide scale.

GEL COAT

Anodizing Yachts has the repair by gel coat within its capabilities. The gel coat repair process is the most appropriate to restore superficial damage to different parts of the boat finished in gel coat and manufactured in fibre reinforced composite.

The gel coat is a polyester coating that serves to protect the laminate against attacks from the environment.

Small dents or chips in the gel coat must be repaired quickly if they have exposed the laminate, since it, being very porous, absorbs water easily, causing the weakening of the structure.

Advantage:

- Excellent water ingress resistance.

- Good resistance to impacts.

- Excellent polish results.

- The use of gel coat for small repairs is a better alternative than doing a paint repair as the need/cost of protection is minimised as well as the risk of over spraying.

- Excellent surface finish.

- Excellent resistance to ultraviolet degradation.